The glass begins to be eplaced by hard polymers, one of them is ETFE. It’sweight – only one percent of the weight of glass; ETFE with stands heavy objects, begins to melt at more than 130 degrees.

The new material- it is a great way to built transparent buildings. ETFE constructions can with stand 200 km per hour wind (5th level hurricane). Resistance is increased by cellular structure, if one detail is damaged, than the load pressure gradually dissolves into the near details. Loss of stability is reached, when 20% of the construction is damaged. Torn ETFE construction comes down, not harming people under it.

Repair is also much easier, comparing to glass structure – it is enough to have adhensive slick. ETFE has an excellent characteristic not to attract dirt, but wash it by rain.

For greater durability, carcass elements are covered with 3 ETFE layers. By adjusting the air volume you can change the shape of details and sunlight traffic.

Between the details of carcass there is a kind of membrane – 0,2-0,05 mm thickness ETFE (ethylene tetrafluoretile), also known as transparent Teflon.It is more than a hundred times lighter than the same area of the glass sheet, so the load on the supporting structure is reduced dozens of times. The maximum length of a single element can reach 147 m, width – 3,2 m. ETFE membrane is resistant to heat- stasble even at 180 ° C. This membrane completely transmits UV rays, however UV ray traffic can be regulated by drawings on both sides of the membrane’s pillow. Membrane structure can be equipped with one or several air spaces, which play a role in thermal insulation properties.

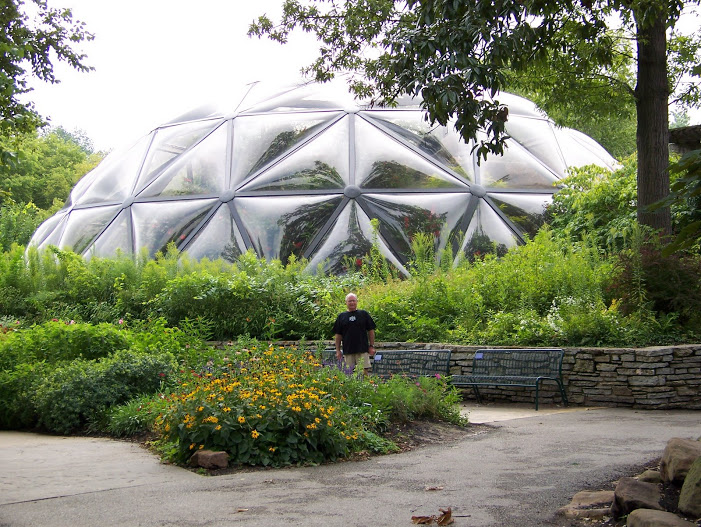

ETFE material was used in 2001 building Eden complex of greenhouses in UK, AllianzArena football stadium in Munich, the Beijing Olimpic stadium and in other facilities. The Beijing Olimpic stadium was designed by Swiss architect group „Herzog & de Meron“.Due to its unusuall roof, constructed from overlapping steel beams, authors called this building “Bird’s Nest”. Constructions with membrane structure are formed from several layers of membrane pillows, and stiffening is made by air inflation inside of the pillow. Air supply system – air compressor, consisting of 2 ventilators, which work independently from each other. If one breaks, the second ventilator will support the system.

Benefits of ETFE membrane:

- Low operating costs;

- For its relatively low weight, it can be used in buildings with limited load capacity;

- Wide range of architectural solutions;

- Self-cleaning surface;

- Inside lightning option.

Types of ETFE membrane:

- transparent;

- transparent matt;

- white, transmitting UV rays;

- white, not transmitting UV rays;

- with screen-printing and gravure covering.

Technical characteristics of ETFE membrane:

- Mass 0,15-0,35 kg/m2;

- Light transmission – 95 %;

- Thermoplastic side from -800 up to +1000C;

- Thickness from 150 nm up to 250 nm;

- Heat transmission (K-value) 2,0 Wt/m2 per hour.

- Sun energy transfer (G-value) 0,77.

Photos:

Transparent ETFE roofs andfacades – MIX.

Transparent ETFE roofs andfacades – MIX.

![]() Naujenos apie ETFE Facebook’e.

Naujenos apie ETFE Facebook’e.

English

English Русский

Русский  Lithuanian

Lithuanian